Start » WJC Gantry

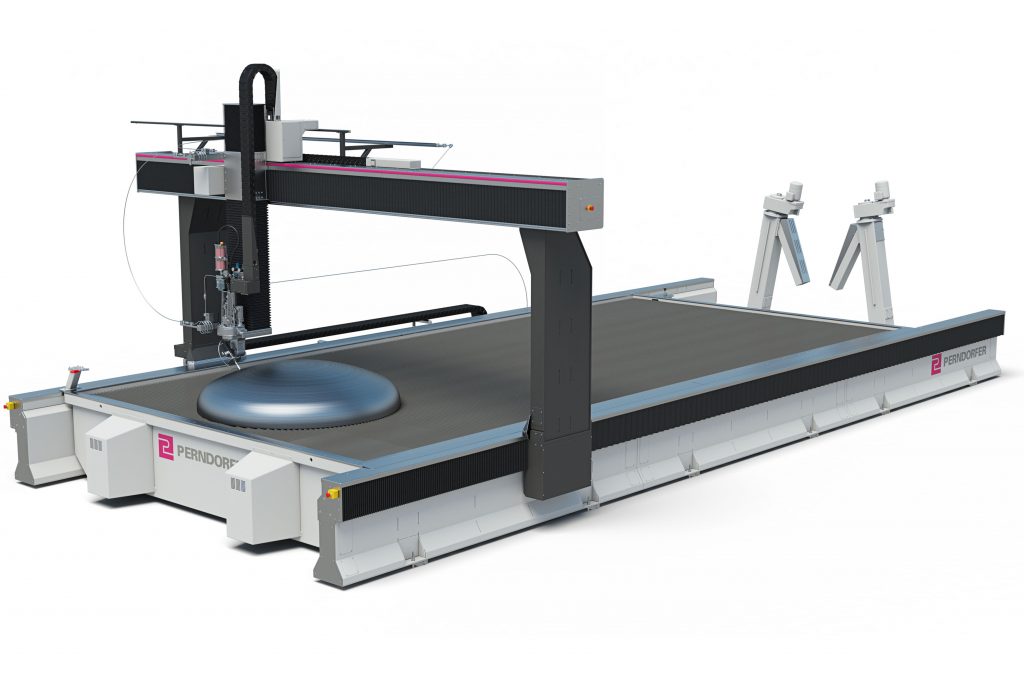

Waterjet cutting machines in the gantry design are used for working on wide widths. As with other designs, emphasis here is also on space-saving construction. All of Perndorfer’s gantry waterjet cutting machines are operated with the gantry drive.

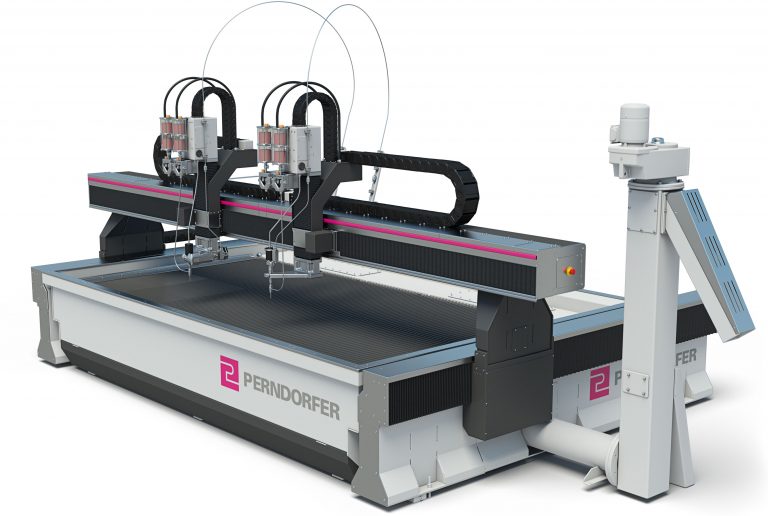

WJC HE Gantry

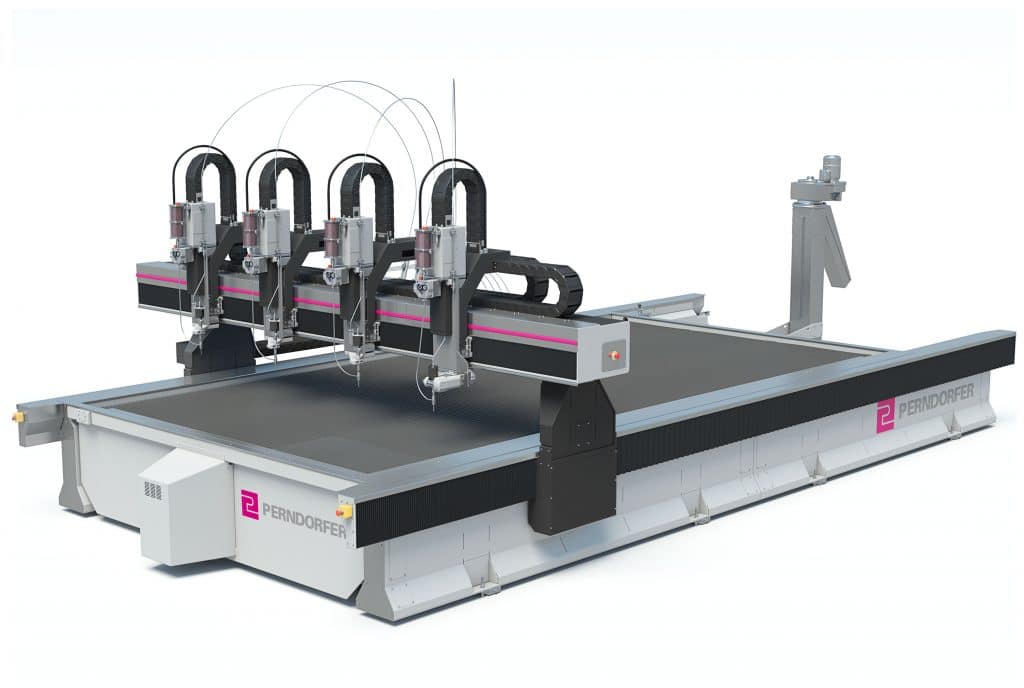

The gantry design is usually used when the working width exceeds 2,500 mm. As with the cantilever design, the machine can be used simultaneously to set up and cut if the working surfaces are large. Even in the case of machines with several heads, the main cutting head can go up and down the entire working area. This makes it easy to work efficiently and economically. Gantry design.Working surface: 4,000 x 3,000 mm – 12,000 x 4,000 mmOther sizes available upon request.

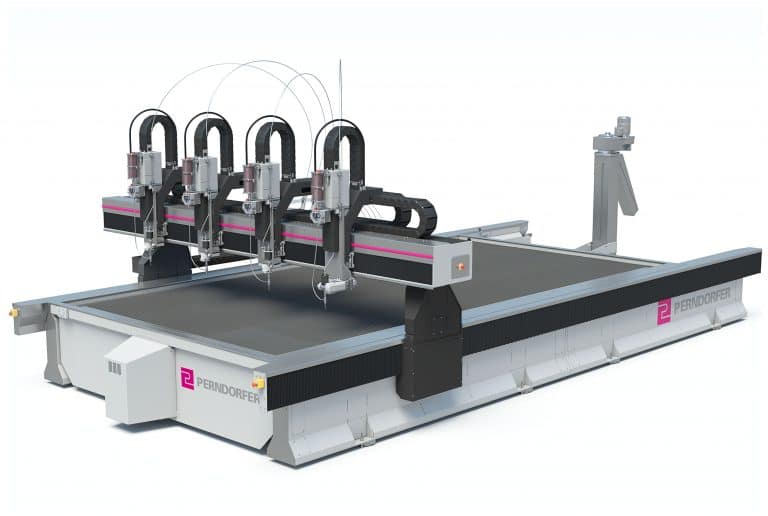

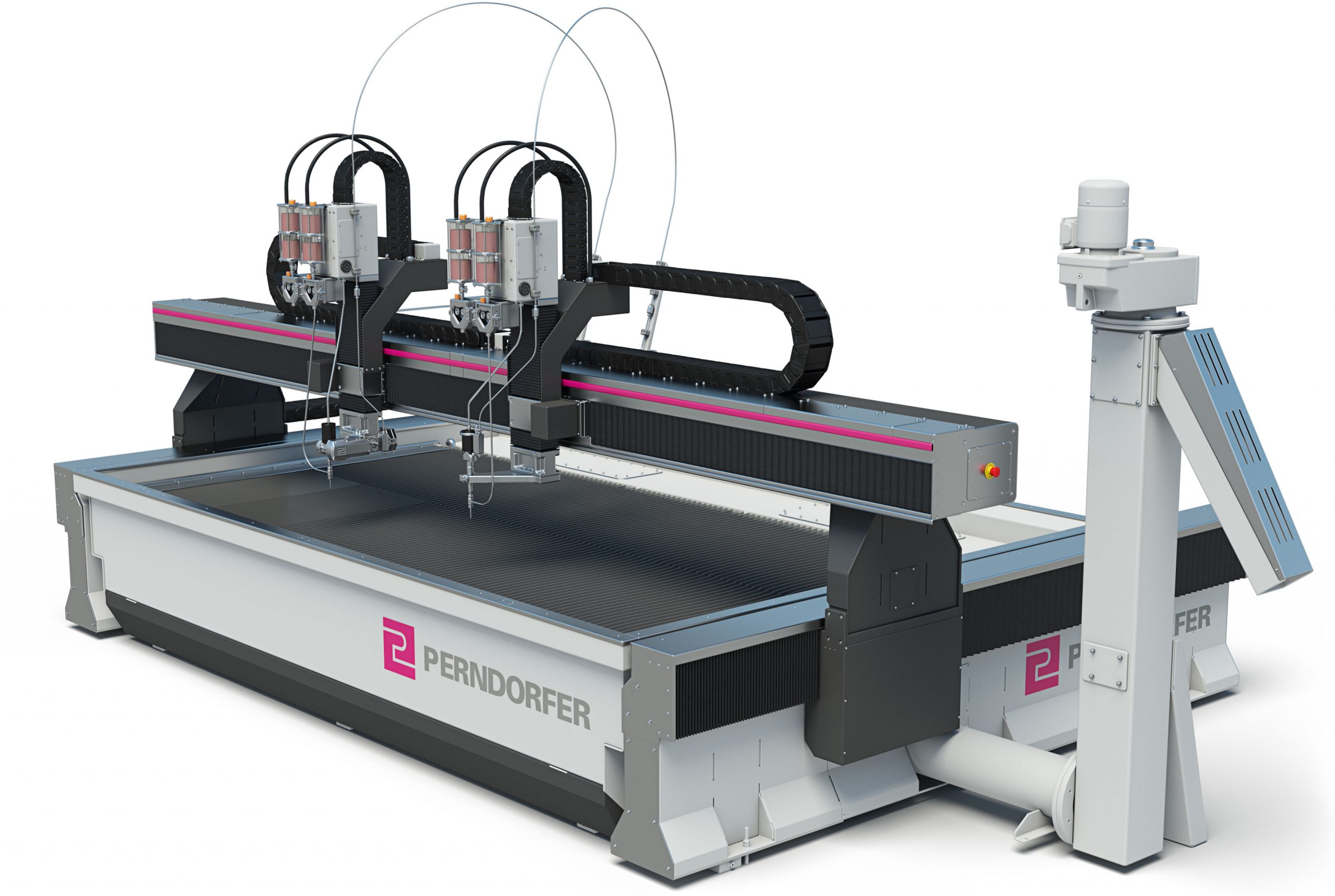

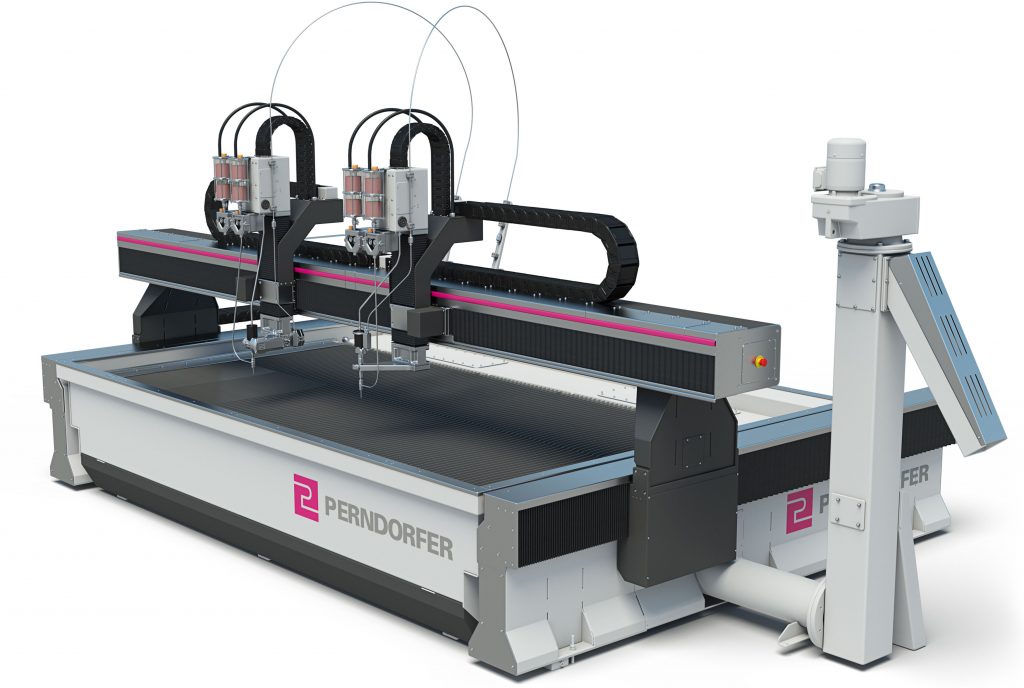

WJC HE Wide Gantry

For some cutting applications such as working simultaneously with two cutting heads and a component size greater than

> > 1,00 mm, the Wide Gantry is the right choice.

It, too, has a lean design and ideal accessibility.

As with all of Perndorfer’s flatbed waterjet cutting machines, the zero stop along the x/y axes guarantees a quick, exact, and convenient setup of the raw material on the cutting table.

Gantry design.

Working surface: 3,000 x 2,000 mm – 4,000 x 4,000 mm

Other sizes available upon request.

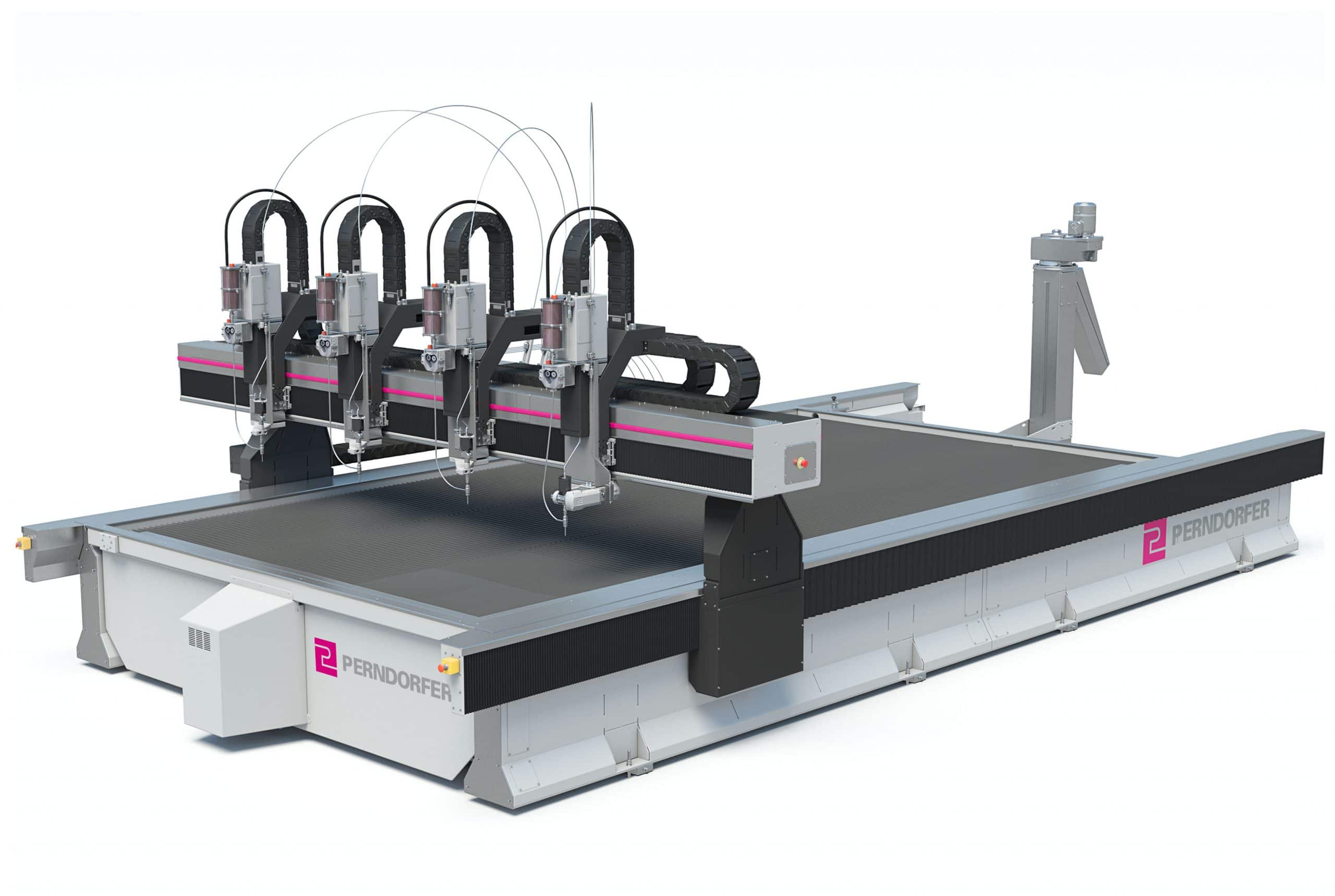

- Perndorfer’s well-liked sludge removal features reliable and low-maintenance sludge removal of the abrasive and sludge.

- The extremely practical zero stop as well as the clamping strip along the entire x axis and the y axis of the cutting table make it possible for the material to be aligned and clamped quickly and reliably.

- Machines with more than one head are designed in such a way that the main cutting head can always go up and down the whole working area.

- The solid construction means stability and utmost precision.

- The user-friendly controls with job management (job queue), real-time display, graphic restart feature, and many more make it easy to use the machine.

- Many components like 3D and bevel cutting heads, a drilling unit, and others

as well as (like the energy-saving HD pump Servo-Jet4000, or various abrasive conveyors) boost the machine’s performance.peripheral equipment

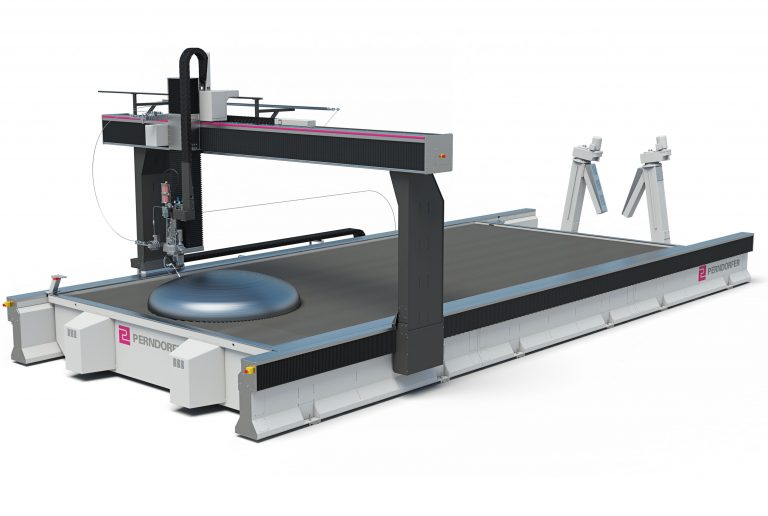

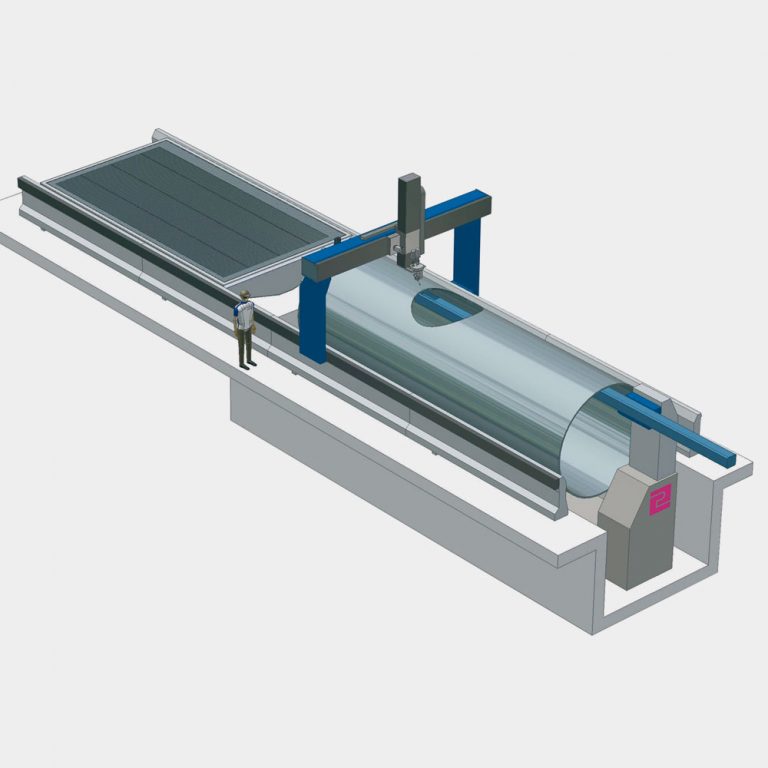

To work on Klopper heads, welded assemblies, complex three-dimensional geometrics, and other material with more space.

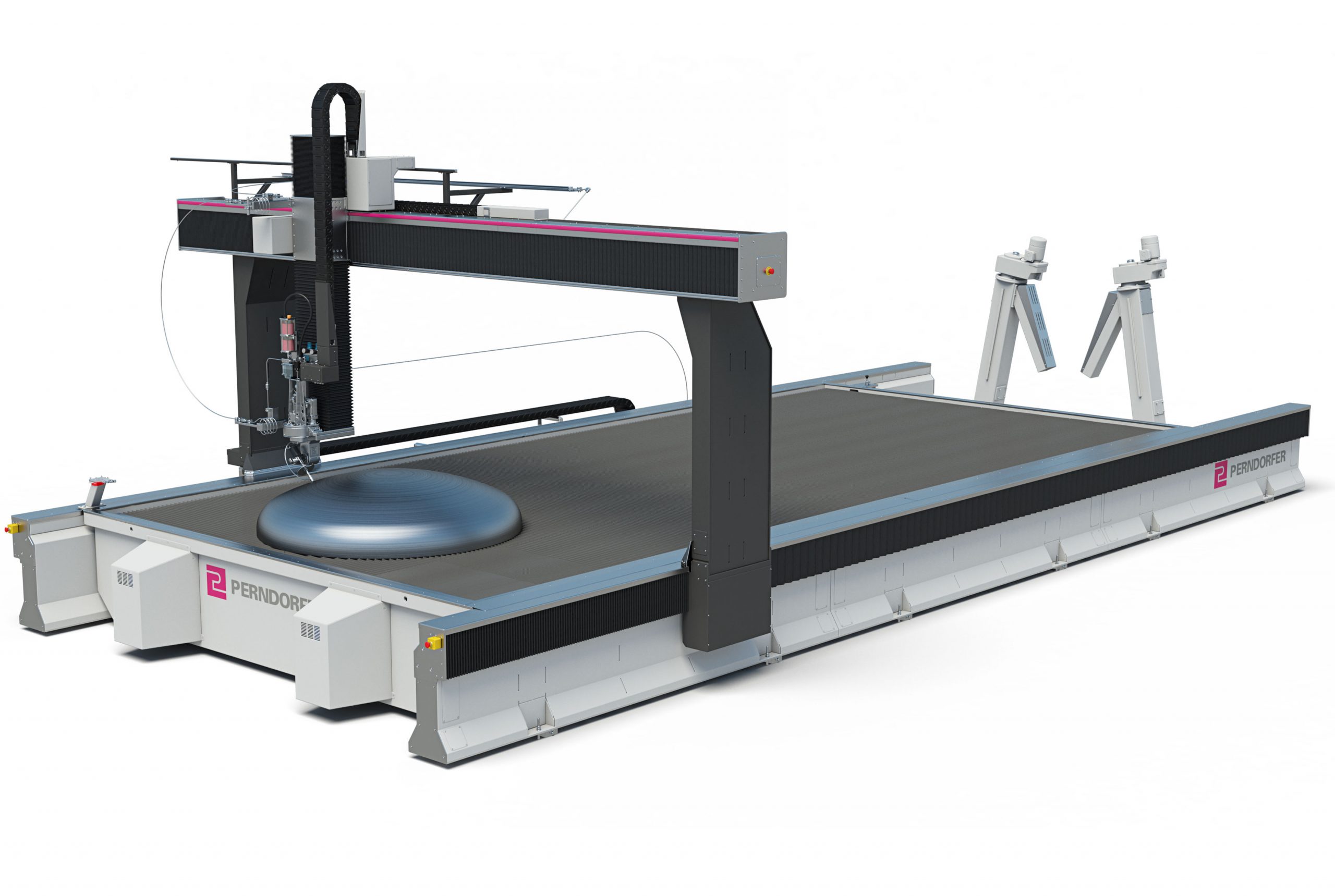

WJC 3D

This machine has a large z axis hub and a full 3D cutting head which give it an advantage over the high gantry design when it comes to accessibility and loading. Thanks to the large z axis hub up to 1,500 mm of Klopper heads, tubes, containers, and constructions can be worked on right on the cutting table.Gantry design.Working surface: 4,000 x 3,000 mm – 12,000 x 4,000 mmOther sizes available upon request.

This application is perfect if samples from welded assemblies from various parts are to be taken using waterjet. Because no heat is added to the material, the structure of the material does not change.

The samples can be permanently engraved by the waterjet and thus marked, which is advantageous for further work steps such as etching in an acid bath. Perndorfer provides not only the right machines, but also a special software designed for this application. Together with the client and the related know-how we develop the project.

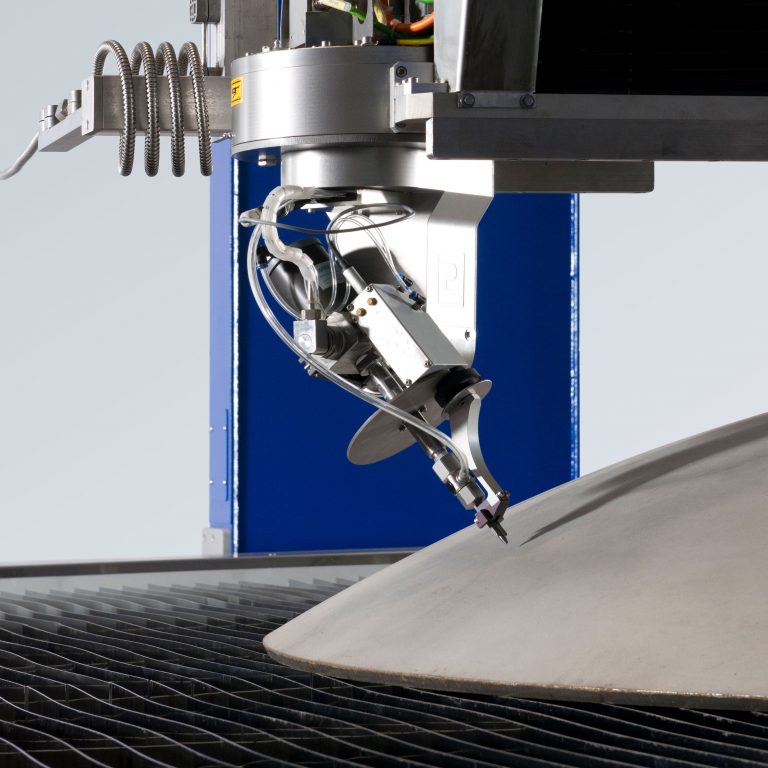

Tubes and containers up to 3,000 mm in diameter can be cut easily with this machine. Larger cutting diameters are possible as a custom design. The patented 3D abrasive head also makes it possible to cut complex contours. The 3D (5 axes) machine can be equipped with a cutting table.

The 3D cutting head ensures an even cutting quality even with complicated contours. With the b axis cuts up to ± 130° are possible. The endlessly rotating c axis has all the advantages of the integrated abrasive technology.